Sistimi ea Mohala oa Phaephe ea Oli e Tsoetseng Pele

Thepa ea Mekaniki ea Phaephe ea SSAW

| sehlopha sa tšepe | matla a fokolang a chai Mpa | bonyane matla a ho tenyetseha Mpa | Tekanyo e fokolang % |

| B | 245 | 415 | 23 |

| X42 | 290 | 415 | 23 |

| X46 | 320 | 435 | 22 |

| X52 | 360 | 460 | 21 |

| X56 | 390 | 490 | 19 |

| X60 | 415 | 520 | 18 |

| X65 | 450 | 535 | 18 |

| X70 | 485 | 570 | 17 |

Sebopeho sa Lik'hemik'hale sa Liphaephe tsa SSAW

| sehlopha sa tšepe | C | Mn | P | S | V+Nb+Ti |

| % e phahameng | % e phahameng | % e phahameng | % e phahameng | % e phahameng | |

| B | 0.26 | 1.2 | 0.03 | 0.03 | 0.15 |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | 0.15 |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X60 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X65 | 0.26 | 1.45 | 0.03 | 0.03 | 0.15 |

| X70 | 0.26 | 1.65 | 0.03 | 0.03 | 0.15 |

Mamello ea Jiometri ea Liphaephe tsa SSAW

| Mamello ea jeometri | ||||||||||

| bophara ba kantle | Botenya ba lebota | ho otloloha | ho se phele hantle | boima | Bophahamo bo boholo ba sefaha sa weld | |||||

| D | T | |||||||||

| ≤1422mm | >1422mm | 15mm | ≥15mm | pheletso ea phaephe 1.5m | bolelele bo feletseng | 'mele oa phaephe | pheletso ea phaephe | T≤13mm | T >13mm | |

| ± 0.5% ≤4mm | joalo ka ha ho lumellanoe | ± 10% | ± 1.5mm | 3.2mm | 0.2% L | 0.020D | 0.015D | '+10% -3.5% | 3.5mm | 4.8mm |

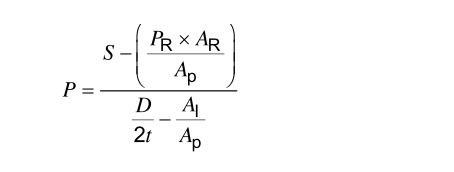

Teko ea Hydrostatic

Selelekela sa Sehlahisoa

Ho Hlahisa Mekhoa e Tsoetseng Pele ea Liphaephe tsa Petroleum: Bokamoso ba lipalangoang tsa eneji tse sebetsang hantle le tse tšepahalang. Ha tlhoko ea oli le khase e ntse e eketseha, tlhoko ea liphaephe tse matla le tse tšepahalang ha e so ka e e-ba kholo ho feta ena. Liphaephe tsa rona tsa X60 SSAW li ka pele ho nts'etsopele ena, tse etselitsoeng ka ho khetheha kaho ea liphaephe tsa peterole le tse hlahisoang ka maemo a holimo a indasteri.

Phaephe ea mohala ea X60 SSAW ke phaephe ea tšepe e potolohang e fanang ka melemo e fapaneng, ho kenyeletsoa matla a ntlafalitsoeng, ho tenyetseha le ho hanyetsa mafome. Likarolo tsena li etsa hore e be ntle bakeng sa ho tsamaisa oli le khase libakeng tse telele, ho netefatsa hore matla a fihla moo a eang teng ka mokhoa o sireletsehileng le o sebetsang hantle.mohala oa phaephe ea olilitsamaiso li etselitsoe ho mamella mathata a tikoloho e thata, e leng se fanang ka khotso ea kelello bakeng sa basebetsi le ba nang le seabo.

Molemo oa Sehlahisoa

E 'ngoe ea melemo e meholo ea phaephe ea mohala oa X60 SSAW ke kaho ea eona e thata. E entsoe ka tšepe ea boleng bo holimo, phaephe ena e potolohang e ka mamella khatello e phahameng le maemo a thata a tikoloho, e leng se etsang hore e be ntle bakeng sa ho tsamaisa oli le khase libakeng tse telele. Ho phaella moo, ts'ebetso ea ho tjheseletsa e potolohang e lumella bolelele ba phaephe bo tsoelang pele, e fokotsa palo ea manonyeletso le libaka tse ka lutlang, ka hona e ntlafatsa ts'epo ea sistimi ea phaephe ka kakaretso.

Ho phaella moo, phaephe ya mohala ya X60 SSAW e tsebahala ka ho boloka ditjeo tsa yona ka katleho. Tshebetso ya tlhahiso e sebetsa hantle, e dumella ditheko tse hlwahlwa ntle le ho beha boleng kotsing. Sena se molemo haholo bakeng sa dikhamphani tse batlang ho ntlafatsa ditjeo tsa tshebetso ha di ntse di netefatsa polokeho le botshepehi ba ditsamaiso tsa tsona tsa diphaephe.

Bofokoli ba Sehlahisoa

Pipe ea X60 SSAW e kanna ea se lokele mefuta eohle ea maemo a sebaka kapa a tikoloho. Libakeng tse nang le mocheso o feteletseng kapa maemo a phahameng a ts'ebetso ea litšisinyeho tsa lefatše, litharollo tse ling tsa boenjiniere li ka hlokahala ho netefatsa botšepehi ba phaephe. Ho feta moo, leha theknoloji ea ho tjheseletsa ka spiral e fana ka melemo e mengata, e ka boela ea lebisa liphephetsong tsa tlhahlobo le tlhokomelo, kaha seam ea weld e ka ba thata ho e fihlella ho feta phaephe ea seam e otlolohileng.

Kopo

Ha tlhoko ea lefats'e ea oli le khase e ntse e eketseha, tlhoko ea litsamaiso tsa lipalangoang tse sebetsang hantle le tse tšepahalang ha e so ka e e-ba ea bohlokoa hakana. E 'ngoe ea litharollo tse sebetsang ka ho fetisisa phephetsong ena ke litsamaiso tsa liphaephe tsa oli tse tsoetseng pele, haholo-holo liphaephe tsa X60 SSAW (Spiral Submerged Arc Welded). Theknoloji ena e ncha e fetola sebaka sa kaho ea liphaephe tsa oli, e netefatsa hore mehloli ea matla e tsamaisoa ka mokhoa o sireletsehileng le o sebetsang.

Phaephe ea mohala ea X60 SSAW e tsebahala ka matla le ho tšoarella ha eona, e leng se etsang hore e be khetho e ntle ka ho fetisisa bakeng sa oli.phaephemerero. Moralo oa eona oa spiral o ntlafatsa ho tenyetseha le ho hanyetsa khatello ea kantle, e leng habohlokoa bakeng sa libaka tse thata tseo lipeipi tsena li sebetsang ho tsona. Ha lik'hamphani tsa eneji li batla ho ntlafatsa ts'ebetso le ho fokotsa litšenyehelo, ho amoheloa ha litsamaiso tse tsoetseng pele tsa lipeipi tse kang X60 SSAW ho ntse ho ata haholo.

Lipotso Tse Botsoang Khafetsa

P1. X60 SSAW Linepipe ke eng?

Phaephe ea Mohala ea X60 SSAW (Spiral Submerged Arc Welded) ke phaephe ea tšepe e potolohang e etselitsoeng kaho ea liphaephe tsa oli. Theknoloji ea eona e ikhethang ea ho tjheseletsa e potolohang e ntlafatsa matla le ho tšoarella, e leng se etsang hore e be khetho e ntle bakeng sa ho tsamaisa oli le khase libakeng tse telele.

P2. Ke hobane'ng ha phaephe ea mohala e phuthetsoeng ka arc e nang le spiral e le khetho ea pele bakeng sa liphaephe tsa oli?

Phaephe ea mohala oa X60 SSAW e ratoa haholo ka lebaka la ho hanyetsa khatello e phahameng le mafome. Sena se netefatsa hore oli le khase li tsamaisoa ka mokhoa o tšepahalang le o sireletsehileng, e leng ntho ea bohlokoa haholo tikolohong ea matla ea kajeno.

P3. Khamphani ea hau e netefatsa boleng ba lihlahisoa tsa hau joang?

Khamphani e latela mehato e tiileng ea taolo ea boleng nakong eohle ea ts'ebetso ea tlhahiso. Re sebelisa theknoloji e tsoetseng pele le basebetsi ba nang le boiphihlelo ho netefatsa hore phaephe e 'ngoe le e 'ngoe ea X60 spiral submarine arc welded line e fihlela maemo a machaba le litlhaloso tsa bareki.

P4. Tšebeliso ea phaephe ea mohala ea X60 SSAW ke efe?

Phaephe ea Mohala ea X60 SSAW e sebelisoa haholo indastering ea oli le khase bakeng sa ho tsamaisa oli e tala, khase ea tlhaho le maro a mang. Ho tenyetseha ha eona ho boetse ho e lumella ho sebelisoa mererong e fapaneng ea kaho le meralo ea motheo.