Melemo le Litšebeliso tsa Li-spiral Welded Tubes Indastering ea Kajeno

Hlahisa:

Masimong a ntseng a hola a boenjiniere le kaho, tšebeliso eaphala e tjheseletsoeng ka spirale ntse e tuma haholo. Liphaephe tsena tse tenyetsehang le tse tšoarellang li kene indastering e fapaneng, li ipakile e le tharollo e ncha bakeng sa lits'ebetso tse fapaneng. Posong ena ea blog, re tla shebisisa haufi-ufi melemo e makatsang e fanoang ke liphaephe tse welded ka spiral le ho hlahloba lits'ebetso tsa tsona tse fapaneng indastering ea sejoale-joale.

Thepa ea Mechini

| sehlopha sa tšepe | matla a fokolang a chai | Matla a tšepe | Bolelele bo fokolang | Matla a fokolang a tšusumetso | ||||

| Botenya bo boletsoeng | Botenya bo boletsoeng | Botenya bo boletsoeng | mochesong oa teko ea | |||||

| 16 | >16≤40 | 3 | ≥3≤40 | ≤40 | -20℃ | 0℃ | 20℃ | |

| S235JRH | 235 | 225 | 360-510 | 360-510 | 24 | - | - | 27 |

| S275J0H | 275 | 265 | 430-580 | 410-560 | 20 | - | 27 | - |

| S275J2H | 27 | - | - | |||||

| S355J0H | 365 | 345 | 510-680 | 470-630 | 20 | - | 27 | - |

| S355J2H | 27 | - | - | |||||

| S355K2H | 40 | - | - | |||||

1. Phaephe e welletsoeng ka spiral ke eng?

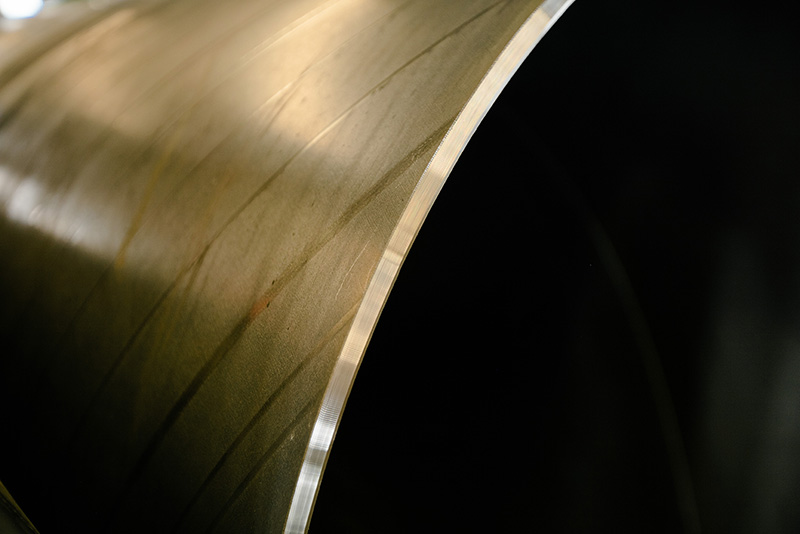

Phaephe e welded ka spiral, joalo ka ha lebitso le bontša, e etsoa ka ho phutholla tšepe khafetsa le ho e tjheseletsa bolelele ba eona ho etsa phaephe e potolohang. Mokhoa ona oa tlhahiso o tiisa matla le botšepehi bo phahameng, o etsang hore lipeipi tsena li be ntle bakeng sa lits'ebetso tse boima.

2. Melemo ea phaephe e tjheseletsoeng ka spiral:

2.1 Matla le ho tšoarella:

Ts'ebetso ea ho tjheseletsa ka sekoting ka tlhaho e fa phaephe matla a phahameng. Sena se li lumella ho mamella likhatello tse phahameng tsa kahare, meroalo e boima le mocheso o feteletseng. Ka hona, li sebelisoa haholo liindastering moo botšepehi ba sebopeho bo leng bohlokoa.

2.2 Khanyetso ea ts'enyeho:

Phaephe e welletsoeng ka spiral e fumaneha ka thepa e fapaneng, ho kenyeletsoa tšepe e sa ruseng le metsoako e sa ruseng. Ho hanyetsa ha tsona mafome ho li etsa hore li be ntle bakeng sa ts'ebeliso indastering ea lik'hemik'hale, oli le khase le kalafo ea metsi. Li eketsa nako ea ts'ebeletso le ho fokotsa kotsi ea ho lutla le nako ea ho se sebetse.

2.3 Katleho ea litšenyehelo:

Ho tjheseletsa ka spiral ho fana ka melemo ya ditjeo ha ho bapiswa le mekgwa ya setso ya tlhahiso ya diphaephe. Sena se bakwa ke nako e fokotsehileng ya tlhahiso le tshebediso e fokotsehileng ya thepa. Ho phaella moo, sebopeho se setle sa diphaephe tse tjheseletsang ka spiral se dumella meralo e ikgethileng le ditharollo tse ikgethileng, ho ntlafatsa ditjeo ka ho fokotsa ditshila le ho fokotsa tlhoko ya disebediswa tse ding.

3. Tšebeliso ea phaephe e phuthetsoeng ka spiral:

3.1 Meaho le Meralo ea Motheo:

Liphaephe tse tjheseditsweng ka spiral li sebelisoa haholo indastering ea kaho, haholo-holo mererong e meholo. Hangata li sebelisoa ho theha meaho ea litšiea, maballo le liqubu. Ka lebaka la matla a eona a phahameng, e ka mamella meroalo e boima le ho hanela matla a mahlakoreng, e leng se etsang hore e lokele kaho ea borokho, mehaho e melelele le metheo e tebileng.

3.2 Indasteri ea oli le khase:

Lefapheng la oli le khase, liphaephe tse tjheseditsweng ka spiral li sebelisoa haholo bakeng sa ho tsamaisa lihlahisoa tsa peterole, khase ea tlhaho le maro a mang. Bokhoni ba phaephe ba ho mamella tikoloho e nang le khatello e phahameng, ho loketse lits'ebetso tsa leoatle le tebileng le ho hanyetsa mafome ho etsa hore e be khetho ea pele bakeng sa liphaephe, li-risers le lits'ebetso tsa leoatleng.

3.3 Boenjiniere ba Mekaniki:

Liphaephe tse tjheseditsweng ka spiral li sebelisoa ka mefuta e fapaneng ea lits'ebetso boenjiniere ba mechini 'me li hlahella ka ho tšoarella ha tsona le ho tenyetseha ha tsona. Li sebelisoa tlhahisong ea mechini, litsamaiso tsa lipalangoang le likarolo tsa sebopeho. Ho feta moo, li bapala karolo ea bohlokoa indastering ea likoloi, li fana ka tšehetso ea sebopeho ka kakaretso ho foreimi le sistimi ea mosi.

Ha re phethela:

Ha indasteri e ntse e tsoela pele ho fetoha, tlhoko ea litharollo tse matla, tse tšoarellang le tse theko e tlaase e ntse e hola. Liphaephe tse tjheseletsoeng ka spiral li fihlela litlhoko tsena ka katleho 'me li fetoha letlotlo la bohlokoa haholo masimong a mangata. Matla a tsona a phahameng, ho hanyetsa mafome le katleho ea litšenyehelo li tiisa boemo ba tsona e le khetho ea pele bakeng sa lits'ebetso tse fapaneng tsa boenjiniere. Ha re ntse re tsoela pele, ho hlakile hore phaephe e tjheseletsoeng ka spiral e tla tsoela pele ho bopa bokamoso ba indasteri ea sejoale-joale.