Hlahisa

Lefapheng la ho kenya liindasteri le nts'etsopele ea meralo ea motheo, liphaephe tsa tšepe li bapala karolo ea bohlokoa ho netefatseng katleho le bophelo bo bolelele ba litsamaiso tse fapaneng. Har'a mefuta e fapaneng ea liphaephe tsa tšepe tse fumanehang,liphaephe tsa tšepe ea k'habone tse tjheseletsoeng ka spiralLiphaephe tsena ke mesebetsi e metle ea boenjiniere, ka lebaka la ho tjheseletsa ha seam e helical e phahameng le mekhoa ea ho tjheseletsa ea arc e helical e ka tlas'a lefatše e sebelisoang tlhahisong ea tsona.

Pipe ea Tšepe ea Khabone e Welded Spiral: Ho Hlōla Mathata

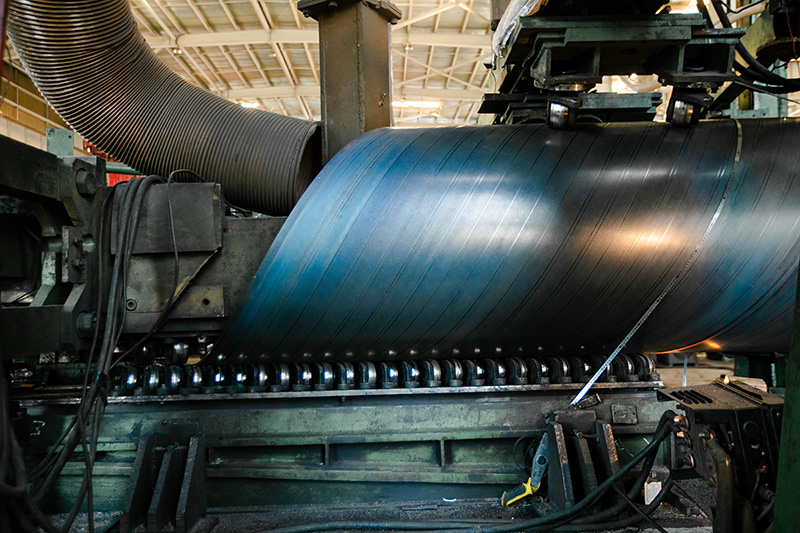

Phaephe ea tšepe ea khabone e phuthetsoeng ka ho tjheseletsa e etsoa ka ho etsa tšepe e strip hore e be sebopeho sa spiral se silindara, seo mathoko a sona a kopantsoeng hammoho ka ho tjheseletsa ka ho tswela pele ka ho tjheseletsa. Liphaephe tsena li khetholloa ho liphaephe tsa setso tse otlolohileng ka ho tjheseletsa ...

Bokgoni ba ho Welding Spiral Seam

Ho tjheseletsa ka seam se spiral ke ts'ebetso ea mantlha tlhahisong ea liphaephe tsa tšepe ea carbon tse tjheseletsoeng ka sekontiri 'me ho kenyelletsa ho tjheseletsa ka ho tsoelang pele mathoko a ka ntle le a ka hare a moqomo oa tšepe o kobehileng. Mokhoa ona oa ho tjheseletsa o se nang sekontiri o netefatsa tlamo e tsitsitseng le e matla ho pholletsa le bolelele ba phaephe, e fokotsang kotsi ea ho lutla kapa liphoso tsa sebopeho.Pipe e otlolohileng ea seam e weldedhape e qoba tlhoko ea matlafatso e eketsehileng, e leng se etsang hore phaephe e be theko e tlase haholo nakong ea ho kenya le ho hlokomela.

Ho Welding ea Arc e Kenelletseng ka Spiral: Bokgoni bo ka Sehloohong ba Boleng bo Phahameng

Ho tjheseletsa arc e qoelitsoeng ka helicalTheknoloji ea (HSAW) e bapala karolo ea bohlokoa ho fihlelleng botšepehi bo phahameng ba sebopeho sa liphaephe tsa tšepe ea carbon tse welded ka spiral. Nakong ea ts'ebetso ena, arc e hlahisoa khafetsa 'me e qoelisoa ka tlas'a lera la flux. Ebe arc e sebelisoa ho qhibilihisa mathōko a strip, e leng se etsang hore ho be le kopanyo pakeng tsa tšepe e qhibilihisitsoeng le substrate. Kopanyo ena e etsa weld e matla, ea boleng bo holimo e nang le thepa e ntle ea mechini joalo ka matla a eketsehileng a ho tsitlella le ho hanyetsa mafome.

Melemo ea Pipe ea Tšepe ea Khabone e Welded Spiral

1. Matla le ho Tšoarella: Theknoloji ea ho tjheseletsa ka hare e fa liphaephe tsena matla a holimo a li lumellang ho mamella khatello e phahameng, meroalo e boima le maemo a leholimo a feteletseng.

2. Katleho ea litšenyehelo: Ho sebelisa liphaephe tsa tšepe ea khabone tse kopantsoeng ka spiral ho ka fokotsa litšenyehelo tsa projeke haholo ka lebaka la bonolo ba ho li kenya le ho se hloke matlafatso a eketsehileng.

3. Ho feto-fetoha ha maemo: Liphaephe tsa tšepe ea khabone tse tjheselitsoeng ka spiral li ka etsoa ka bophara, bolelele le botenya bo fapaneng, e leng se etsang hore li lokele mefuta e mengata ea lits'ebetso tsa indasteri.

4. E Hanela Mafome: Li-weld tsa HSAW tsa boleng bo holimo li netefatsa hore liphaephe tsena li na le khanyetso e ntle ea mafome, li lelefatsa bophelo ba tsona ba ts'ebeletso esita le libakeng tse thata.

Ha re phethela

Bokgoni ba ho welding ka seam e potolohang le ho welding ka arc e kenelletseng ka hare ho spiral bo fetotse tlhahiso ya diphaephe tsa tshepe. Matla a phahameng, ho tshwarella, le ho boloka ditjeo ha phaephe ya tshepe ya khabone e welletsoeng ka hare ho spiral ho etsa hore e be kgetho e kgethwang bakeng sa diindasteri tse ngata. Bokgoni ba tsona ba ho mamella kgatello ya maikutlo, ho hlola ho fetoha ha sebopeho le ho hanela mafome bo di etsa mohlala wa bokgabane ba boenjiniere. Ka tlhoko e ntseng e eketseha ya meralo ya motheo e sebetsang hantle le e tshepahalang, diphaephe tsa tshepe ya khabone e welletsoeng ka hare ho spiral ntle ho pelaelo di tla bapala karolo ya bohlokwa ho bopeng bokamoso bo tsitsitseng le bo hokahaneng.

Nako ea poso: Phato-24-2023