Matla le Botšepehi ba Liphaephe tsa Sebopeho tse Sekoti: Tlhahlobo e Tebileng ea Pipe e Welded ea Arc e Kenngoeng ka Sekoting le Pipe ea Line ea API 5L

Hlahisa:

Lefatšeng la kaho le nts'etsopele ea meralo ea motheo, ho khetha thepa e nepahetseng ho bohlokoa.Liphaephe tsa sebopeho tse nang le karolo e se nang letho e bapala karolo ea bohlokoa ho faneng ka matla, ho tšoarella le ho tšepahala mererong e fapaneng. Ho blog ena, re tla hlahloba litšobotsi le melemo ea mefuta e 'meli ea bohlokoa ea phaephe ea sebopeho: phaephe e phuthetsoeng ka arc e spiral le phaephe ea mohala ea API 5L.

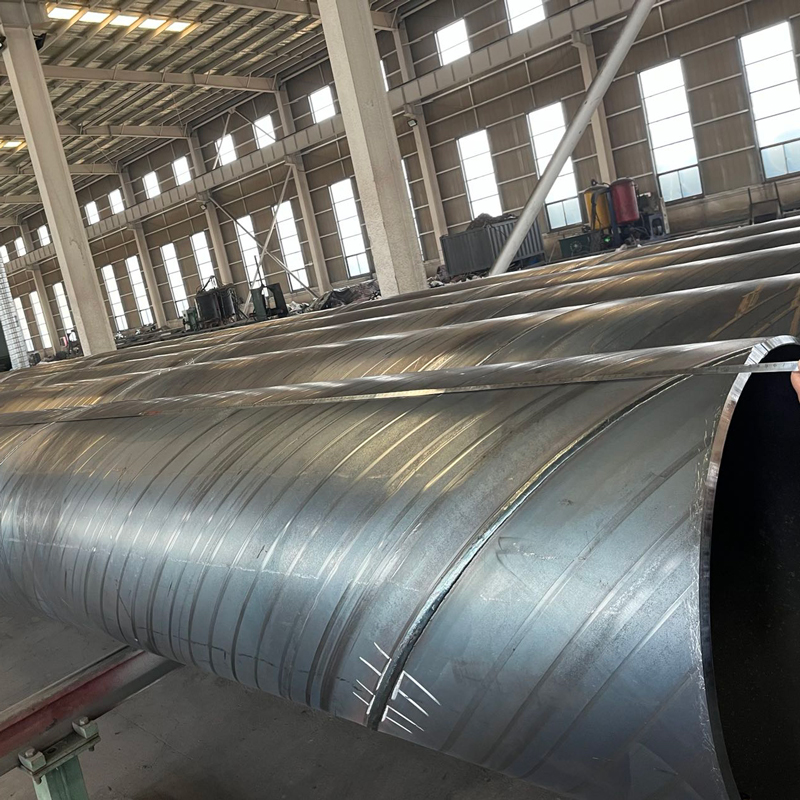

Phaephe e phuthetsoeng ka arc e koahetsoeng ka spiral:

Phaephe e qoelitsoeng ka arc welded (SAW), e tsejoang hape e le phaephe ea SSAW, e sebelisoa lits'ebetsong tse fapaneng. Tšobotsi e ikhethang eaPhaephe ea SSAW ke li-spiral seams tsa eona, tse fanang ka matla a maholo le bokhoni ba ho jara moroalo ha li bapisoa le mefuta e meng ea liphaephe. Moralo ona o ikhethang o thusa ho aba khatello ea maikutlo ka ho lekana ho pholletsa le phaephe, e leng se etsang hore e be e loketseng merero e hlokang botsitso ba sebopeho.

Thepa ea Mekaniki ea phaephe ea SSAW

| sehlopha sa tšepe | matla a fokolang a chai | bonyane matla a ho tenyetseha | Tekanyo e fokolang |

| B | 245 | 415 | 23 |

| X42 | 290 | 415 | 23 |

| X46 | 320 | 435 | 22 |

| X52 | 360 | 460 | 21 |

| X56 | 390 | 490 | 19 |

| X60 | 415 | 520 | 18 |

| X65 | 450 | 535 | 18 |

| X70 | 485 | 570 | 17 |

Sebopeho sa lik'hemik'hale tsa liphaephe tsa SSAW

| sehlopha sa tšepe | C | Mn | P | S | V+Nb+Ti |

| % e phahameng | % e phahameng | % e phahameng | % e phahameng | % e phahameng | |

| B | 0.26 | 1.2 | 0.03 | 0.03 | 0.15 |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | 0.15 |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X60 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X65 | 0.26 | 1.45 | 0.03 | 0.03 | 0.15 |

| X70 | 0.26 | 1.65 | 0.03 | 0.03 | 0.15 |

Mamello ea jeometri ea liphaephe tsa SSAW

| Mamello ea jeometri | ||||||||||

| bophara ba kantle | Botenya ba lebota | ho otloloha | ho se phele hantle | boima | Bophahamo bo boholo ba sefaha sa weld | |||||

| D | T | |||||||||

| ≤1422mm | >1422mm | 15mm | ≥15mm | pheletso ea phaephe 1.5m | bolelele bo feletseng | 'mele oa phaephe | pheletso ea phaephe | T≤13mm | T >13mm | |

| ± 0.5% | joalo ka ha ho lumellanoe | ± 10% | ± 1.5mm | 3.2mm | 0.2% L | 0.020D | 0.015D | '+10% | 3.5mm | 4.8mm |

Teko ea Hydrostatic

Phaephe e tla mamella teko ea hydrostatic ntle le ho dutla ka har'a seam ea weld kapa 'mele oa phaephe.

Li-jointer ha li hloke ho hlahlojoa ka hydrostatic, ha feela likarolo tsa phaephe tse sebelisitsoeng ho tšoaea li-jointer li lekoa ka katleho ka hydrostatic pele ho ts'ebetso ea ho kopanya.

Ho latela morao:

Bakeng sa phaephe ea PSL 1, moetsi o tla theha le ho latela mekhoa e ngotsoeng ea ho hlokomela:

Boitsebiso ba mocheso ho fihlela liteko tsohle tse amanang tsa chmical li etsoa 'me ho latela litlhoko tse boletsoeng ho bontšoa.

Boitsebiso ba yuniti ea teko ho fihlela liteko tsohle tse amanang tsa mechini li etsoa 'me ho latela litlhoko tse boletsoeng ho bontšoa.

Bakeng sa phaephe ea PSL 2, moetsi o tla theha le ho latela mekhoa e ngotsoeng bakeng sa ho boloka boitsebiso ba mocheso le boitsebiso ba yuniti ea teko bakeng sa phaephe e joalo. Mekhoa e joalo e tla fana ka mokhoa oa ho sala bolelele bofe kapa bofe ba phaephe ho ea yuniti e nepahetseng ea teko le liphetho tse amanang le liteko tsa lik'hemik'hale.

E 'ngoe ea melemo e meholo ea phaephe ea SSAW ke ho tenyetseha ha eona tlhahisong. Liphaephe tsena li ka hlahisoa ka boholo bo fapaneng, bophara le botenya 'me li ka fetoloa ho fihlela litlhoko tsa projeke e itseng. Ho phaella moo, liphaephe tse phuthetsoeng ka arc tse koahetsoeng ka spiral hangata li entsoe ka tšepe ea boleng bo holimo, e leng se etsang hore li se ke tsa bola le ho netefatsa bophelo ba ts'ebeletso bo bolelele.

Pipe ea Mohala ea API 5L:

Phaephe ea mola oa API 5Lke phaephe e sebediswang haholo ya sebopeho sa karolo e se nang letho e fihlelang maemo a American Petroleum Institute (API). Diphaephe tsena di etseditswe ho tsamaisa maro, jwalo ka oli le kgase ya tlhaho, maetong a malelele. Phaephe ya mola wa API 5L e tsebahala ka matla a yona a hodimo, ho tshwarella le ho hanyetsa maemo a feteletseng a tikoloho.

Ts'ebetso ea tlhahiso ea phaephe ea mohala ea API 5L e kenyelletsa mehato e tiileng ea taolo ea boleng ho netefatsa hore ea tšepahala. Liphaephe tsena li entsoe ka tšepe ea carbon 'me li na le thepa e ntle ea mechini. Ho khomarela ka tieo litekanyetso tsa API ho netefatsa hore liphaephe tsena li ka mamella khatello e phahameng le liphetoho tsa mocheso, e leng se etsang hore li lokele lits'ebetso tsa bohlokoa indastering ea oli le khase.

Melemo e kopaneng:

Ha phaephe e welded ka arc e kenelletseng ka hare ho spiral le phaephe ya mola ya API 5L di kopantswe, di fana ka botshepehi le ho tshepahala ho sa bapisweng le sebopeho. Di-spiral seams tsa phaephe ya SSAW hammoho le matla le ho tshwarella ha phaephe ya mola ya API 5L di theha sistimi e matla ya tshehetso ya sebopeho.

Ntle le melemo ea tsona e fapaneng, ho lumellana ha phaephe e welded ka arc e spiral e kentsoeng ka har'a metsi le phaephe ea mohala ea API 5L ho eketsa katleho ea merero ea liphaephe. Ho feto-fetoha ha phaephe ea SSAW ho lumella khokahano e bonolo le phaephe ea mohala ea API 5L, ho netefatsa phallo e se nang sekoli ea metsi ka har'a marang-rang a liphaephe.

Ha re phethela:

Liphaephe tsa meaho tse nang le likarolo tse sekoti li bohlokoa haholo ha ho hahoa meralo ea motheo e matla. Tšebeliso e kopaneng ea phaephe ea SSAW le phaephe ea mohala ea API 5L e fana ka tharollo e matla e fanang ka matla, ho tšoarella le ho tšepahala bakeng sa merero e fapaneng. Ebang ke ho tšehetsa metheo ea meaho e melelele kapa ho tsamaisa metsi a bohlokoa libakeng tse telele, liphaephe tsena li bapala karolo ea bohlokoa ho netefatseng nako e telele le botsitso ba meralo ea motheo ea rona. Ka ho sebelisa matla a phaephe e phuthetsoeng ka arc e spiral le ho tšepahala ha phaephe ea mohala ea API 5L, baenjiniere ba ka haha motheo o tiileng bakeng sa bokamoso bo betere.