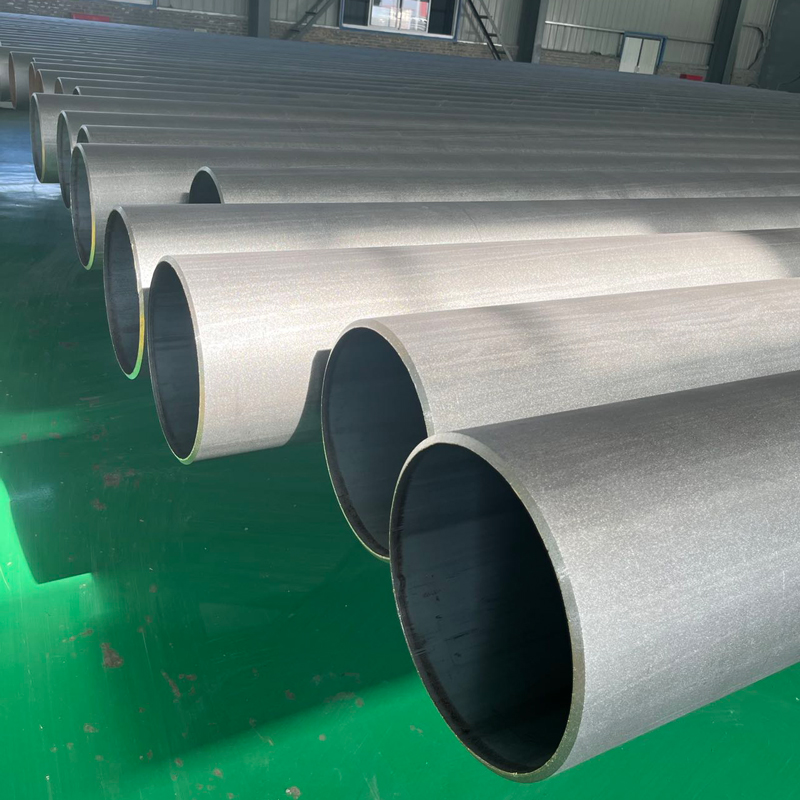

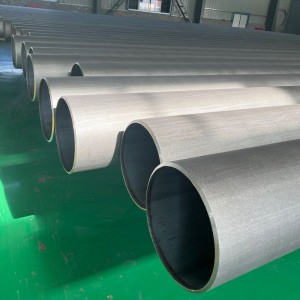

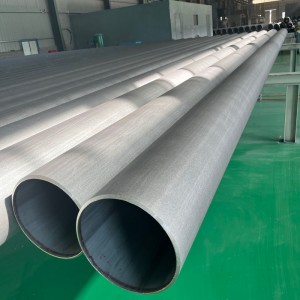

Liaparo tsa Epoxy tse kopantsoeng le Fusion Awwa C213 Standard

Thepa ea 'mele ea thepa ea phofo ea epoxy

Matla a khoheli a itseng ho 23℃: bonyane 1.2 mme boholo ba 1.8

Tlhahlobo ea sefe: boholo ba 2.0

Nako ea jel ho 200 ℃: ka tlase ho 120s

Ho hlwekisa ka ho phatloha ha mollo

Mahlakore a tšepe a hlobotseng a lokela ho hloekisoa ka ho phatloha ho hoholo ho latela SSPC-SP10/NACE No. 2 ntle le haeba moreki a boletse ka tsela e 'ngoe. Paterone ea ankora ea ho phatloha kapa botebo ba profil e tla ba 1.5 mil ho isa ho 4.0 mil (38 µm ho isa ho 102 µm) e lekanngoang ho latela ASTM D4417.

Ho futhumatsa

Phaephe e hloekisitsoeng e lokela ho futhumatsoa mochesong o ka tlase ho 260℃, mohloli oa mocheso o ke ke oa silafatsa bokaholimo ba phaephe.

Botenya

Phofo ea ho roala e tla sebelisoa phaepheng e chesitsoeng esale pele ka botenya bo tšoanang ba filimi ea ho lokisa e seng ka tlase ho 12 mils (305μm) ka ntle kapa kahare. Botenya bo boholo bo ke ke ba feta 16 mils (406μm) ntle le haeba e khothalelitsoe ke moetsi kapa e boletsoeng ke morekisi.

Teko ea ts'ebetso ea epoxy e sa khethoang

Moreki a ka 'na a totobatsa liteko tse ling ho netefatsa ts'ebetso ea epoxy. Mekhoa e latelang ea liteko, eo kaofela e lokelang ho etsoa meheleng ea liteko tsa liphaephe tsa tlhahiso, e ka hlalosoa:

1. Maro a karolo e tšekaletseng.

2. Menyetla ya sebopeho.

3. Tlhahlobo ea mocheso (DSC).

4. Ho tetebela ho sa feleng (ho kobeha).

5. Ho inela ka metsi.

6. Tšusumetso.

7. Teko ea ho arohana ha Cathodic.