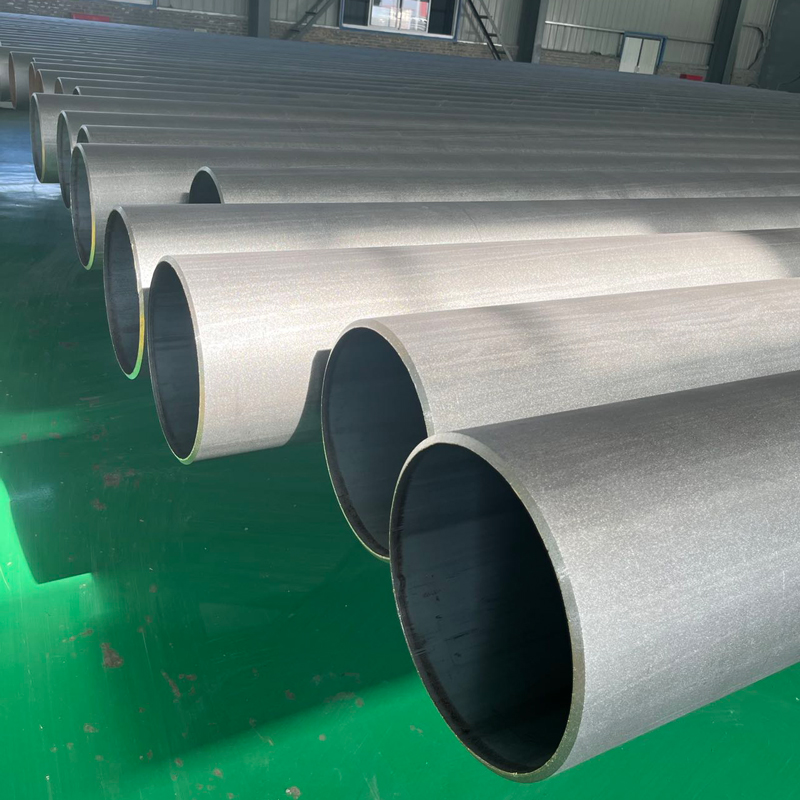

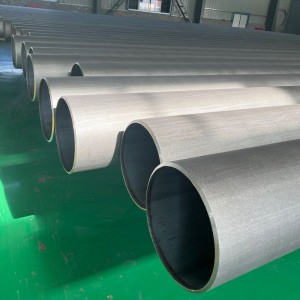

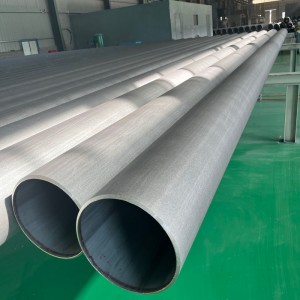

Liaparo tsa Fusion-Bonded Epoxy Awwa C213 Standard

Lintho tsa 'mele tsa lisebelisoa tsa phofo ea epoxy

Matla a khoheli a khethehileng ho 23℃: bonyane 1.2 le boholo ba 1.8

Tlhahlobo ea sieve: boholo ba 2.0

Nako ea gel ho 200 ℃: ka tlase ho 120s

Ho hloekisa ho phatloha ha abrasive

Libaka tsa tšepe tse se nang letho li tla hloekisoa ka ho phatloha ho hoholo ho latela SSPC-SP10/NACE No. 2 ntle le haeba ho boletsoe ka tsela e 'ngoe ke moreki.Paterone ea anchor ea ho phatloha kapa botebo ba profaele e tla ba 1.5 mil ho isa ho 4.0 mil(38 µm ho ea ho 102 µm) e lekantsoeng ho latela ASTM D4417.

Ho futhumatsa

Pipe e hloekisitsoeng e lokela ho futhumatsoa ka mocheso o ka tlase ho 260 ℃, mohloli oa mocheso o ke ke oa silafatsa bokaholimo ba phala.

Botenya

Phofo ea ho roala e tla sebelisoa phala e chesitsoeng pele ho mocheso o lekanang oa filimi e sa feteng 12 mils (305μm) ka ntle kapa ka hare.Botenya bo boholo bo ke ke ba feta 16 mils(406μm) ka lebitso ntle le haeba bo khothalelitsoe ke moetsi kapa bo hlalositsoe ke moreki.

Teko ea boikhethelo ea ts'ebetso ea epoxy

Moreki a ka hlakisa tlhahlobo e eketsehileng ho theha ts'ebetso ea epoxy.Mekhoa e latelang ea tlhahlobo, eo kaofela e tla etsoa ka mehele ea tlhahlobo ea lipeipi tsa tlhahiso, e ka hlalosoa:

1. Porosity ea likarolo tse fapaneng.

2. Interface porosity.

3. Tlhahlobo ea mocheso (DSC).

4. Mathata a sa feleng (bendability).

5. Koahela metsi.

6. Tšusumetso.

7. Teko ea ho tlosoa ha Cathodic.