Bokgoni ba Sistimi ea Piping le Polokeho ka Liphaephe tsa Tšepe tse Potolohang tsa S235 JR

Selelekela:

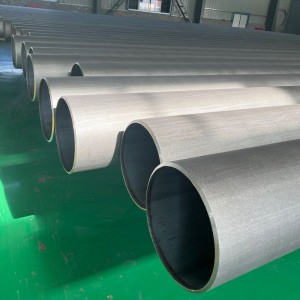

Sechabeng sa mehleng ena, ho tsamaisoa ha metsi le likhase ka katleho ho bohlokoa liindastering tse ngata. E 'ngoe ea lintlha tsa bohlokoa ho netefatsa ts'ebetso e boreleli ea hausistimi ea mohala oa liphaepheke ho khetha liphaephe tse nepahetseng. Har'a likhetho tse fapaneng tse fumanehang,Pipe ea Tšepe e Kobehileng ea S235 JRke khetho e tšepahalang ka lebaka la boleng ba eona bo phahameng. Blog ena e ikemiselitse ho hlahloba melemo ea ho sebelisa phaephe ea tšepe e spiral ea S235 JR lits'ebetsong tsa liphaephe, e shebane le sebopeho sa eona se phuthetsoeng ka spiral.

Thepa ea Mechini

| sehlopha sa tšepe | matla a fokolang a chai | Matla a tšepe | Bolelele bo fokolang | Matla a fokolang a tšusumetso | ||||

| Botenya bo boletsoeng | Botenya bo boletsoeng | Botenya bo boletsoeng | mochesong oa teko ea | |||||

| 16 | >16≤40 | 3 | ≥3≤40 | ≤40 | -20℃ | 0℃ | 20℃ | |

| S235JRH | 235 | 225 | 360-510 | 360-510 | 24 | - | - | 27 |

| S275J0H | 275 | 265 | 430-580 | 410-560 | 20 | - | 27 | - |

| S275J2H | 27 | - | - | |||||

| S355J0H | 365 | 345 | 510-680 | 470-630 | 20 | - | 27 | - |

| S355J2H | 27 | - | - | |||||

| S355K2H | 40 | - | - | |||||

Sebopeho sa Lik'hemik'hale

| Sehlopha sa tšepe | Mofuta oa ho tlosa oksijene a | % ka boima, boholo | ||||||

| Lebitso la tšepe | Nomoro ea tšepe | C | C | Si | Mn | P | S | Nb |

| S235JRH | 1.0039 | FF | 0,17 | — | 1,40 | 0,040 | 0,040 | 0.009 |

| S275J0H | 1.0149 | FF | 0,20 | — | 1,50 | 0,035 | 0,035 | 0,009 |

| S275J2H | 1.0138 | FF | 0,20 | — | 1,50 | 0,030 | 0,030 | — |

| S355J0H | 1.0547 | FF | 0,22 | 0,55 | 1,60 | 0,035 | 0,035 | 0,009 |

| S355J2H | 1.0576 | FF | 0,22 | 0,55 | 1,60 | 0,030 | 0,030 | — |

| S355K2H | 1.0512 | FF | 0,22 | 0,55 | 1,60 | 0,030 | 0,030 | — |

| a. Mokhoa oa ho tlosa oxidation o khethiloe ka tsela e latelang: FF: Tšepe e bolailoeng ka botlalo e nang le likarolo tse tlamang naetrojene ka bongata bo lekaneng ho tlama naetrojene e fumanehang (mohlala, bonyane 0,020 % kakaretso ea Al kapa 0,015 % Al e qhibilihang). b. Boleng bo phahameng ka ho fetisisa ba naetrojene ha bo sebetse haeba sebopeho sa lik'hemik'hale se bontša bonyane kakaretso ea Al ea 0,020% ka karolelano ea bonyane ea Al/N ea 2:1, kapa haeba ho na le likarolo tse ling tse lekaneng tsa N-binding. Likarolo tsa N-binding li tla tlalehoa Tokomaneng ea Tlhahlobo. | ||||||||

Teko ea Hydrostatic

Bolelele bo bong le bo bong ba phaephe bo tla lekoa ke moetsi ho ya ka kgatello ya hydrostatic e tla hlahisa leboteng la phaephe kgatello ya bonyane 60% ya matla a bonyane a tlhahiso a boletsweng mochesong wa kamore. Kgatello e tla laolwa ke equation e latelang:

P=2St/D

Liphetoho tse Lumellehang Boima le Litekanyo

Bolelele bo bong le bo bong ba phaephe bo tla bewa ka thoko mme boima ba yona ha bo a lokela ho fapana ho feta 10% ho feta kapa 5.5% tlasa boima ba yona ba kgopolo-taba, bo balwang ho sebediswa bolelele ba yona le boima ba yona ka bolelele ba yuniti.

Bophara ba kantle ha boa lokela ho fapana ho feta ± 1% ho tloha bophara bo boletsoeng ba kantle bo boletsoeng ka lebitso.

Botenya ba lebota ntlheng efe kapa efe ha boa lokela ho feta 12.5% tlasa botenya ba lebota bo boletsoeng

1. Utloisisa phaephe ea tšepe e potolohang ea S235 JR:

Phaephe ea tšepe e potolohang ea S235 JRke phaephe e tjheseletsang ka sekontiri e sebediswang haholo ditsamaisong tsa diphaephe. Di entswe ka tshepe ya boleng bo hodimo ho latela maemo a matjhaba, ho netefatsa ho tshwarella le matla a phahameng. Tshebetso ya tlhahiso e kenyelletsa ho thehwa ha di-spiral tsa di-strips tsa tshepe tse tswelang pele, tse ntan'o tjheseletsa ka bolelele bo lakatsehang. Mokgwa ona wa kaho o fa diphaephe melemo e meholo ho feta diphaephe tsa setso tse otlolohileng.

2. Melemo ea kaho ea phaephe e tjheseletsoeng ka spiral:

Kaho ea spiral weld ea S235 JR Spiral Steel Pipe e fana ka melemo e mengata lits'ebetsong tsa liphaephe. Taba ea pele, li-spiral weld tse tsoelang pele li ntlafatsa botšepehi ba sebopeho sa phaephe, e leng se etsang hore e hanele haholo likhatello tsa kahare le tsa kantle. Sebopeho sena se boetse se netefatsa kabo e lekanang ea mojaro, se fokotsa kotsi ea ho hloleha ha phaephe. Ho phaella moo, sebopeho sa spiral sa phaephe se felisa tlhoko ea matlafatso ea kahare, ka hona se ntlafatsa bokhoni ba phallo le ho fokotsa tahlehelo ea khatello nakong ea phetisetso ea mokelikeli. Bokaholimo bo sa se nang sekoli bo tsoelang pele ba phaephe ea spiral bo fokotsa kotsi ea ho lutla 'me bo ntlafatsa polokeho le katleho ea sistimi ea liphaephe.

3. Ntlafatsa ho tšoarella le ho tenyetseha:

Pipe ea Tšepe e Kobehang ea S235 JR e fana ka ho tšoarella ho hoholo ka lebaka la thepa ea eona ea kaho ea boleng bo holimo. Li hanela mafome, ho hohlana le maemo a leholimo a feteletseng, e leng se etsang hore li be ntle bakeng sa lits'ebetso tse fapaneng ho kenyeletsoa le lipalangoang tsa oli le khase, litsamaiso tsa metsi le merero ea meralo ea motheo. Ho feto-fetoha ha liphaephe tsena ho li lumella ho fetoloa habonolo ho fihlela litlhoko tse itseng tsa projeke. Ho feta moo, li bonolo ho li kenya le ho li hlokomela, e leng se eketsang botle ba tsona le ho thusa ho fella ka sistimi ea liphaephe e theko e tlaase le e bolokang nako.

4. Melemo ea tikoloho le botsitso:

Ho fetohela ho phaephe ea tšepe e potolohang ea S235 JR lits'ebetsong tsa liphaephe le hona ho ka tlisa melemo e meholo tikolohong. Bophelo ba tsona bo bolelele le ho hanyetsa ho senyeha ho fokotsa tlhoko ea ho nkeloa sebaka khafetsa, e leng se fellang ka ho fokotsa khabone e ntšang le ho hlahisa litšila tse fokolang. Ho feta moo, ho sebelisoa hape ha tšepe ho etsa hore liphaephe tsena e be khetho e tsitsitseng ho latela melao-motheo ea moruo o chitja. Ka ho sebelisa liphaephe tsa tšepe tse potolohang tsa S235 JR, liindasteri li ka netefatsa mokhoa o mosa haholoanyane tikolohong le o nang le boikarabelo ba ho tsamaisa metsi, ka hona li khothalletsa bokamoso bo botala.

Qetello:

Tšebeliso ea phaephe ea tšepe e potolohang ea S235 JR lits'ebetsong tsa liphaephe e fana ka melemo e mengata ea bohlokoa, ho kenyeletsoa le ho tšoarella ho matlafalitsoeng, polokeho le katleho. Sebopeho se kopantsoeng ka spiral se netefatsa botšepehi ba sebopeho sa sona 'me se fana ka phepelo e tšepahalang ea mokelikeli bakeng sa liindasteri tse fapaneng. Ka ho kenyelletsa mahlale a tsoetseng pele joalo ka ana, re bula tsela bakeng sa litsamaiso tsa liphaephe tse tsitsitseng le tse tšepahalang haholoanyane.